Factory

CRUSE Factory takes your scans to the third dimension, giving you full control over 3D, gloss, and depth acquisition.

With Factory, you not only capture the color, but also the surface structure of the scanned items.

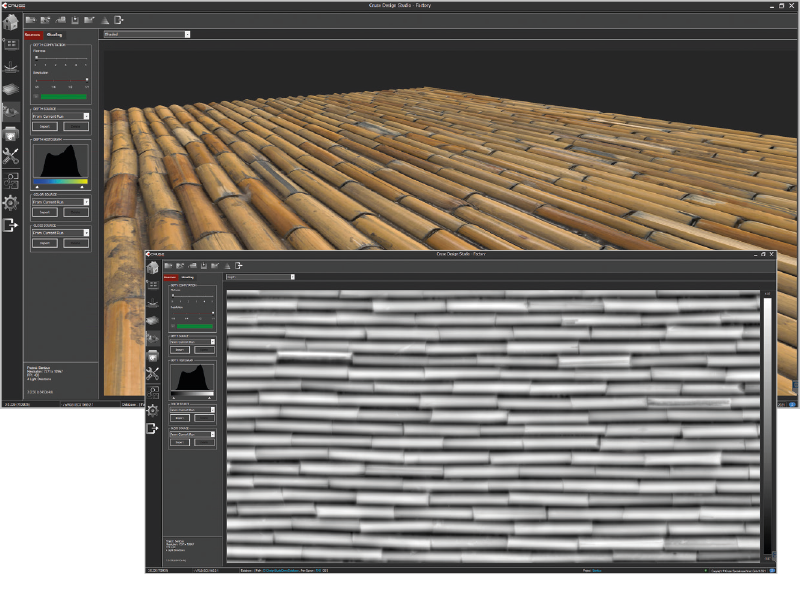

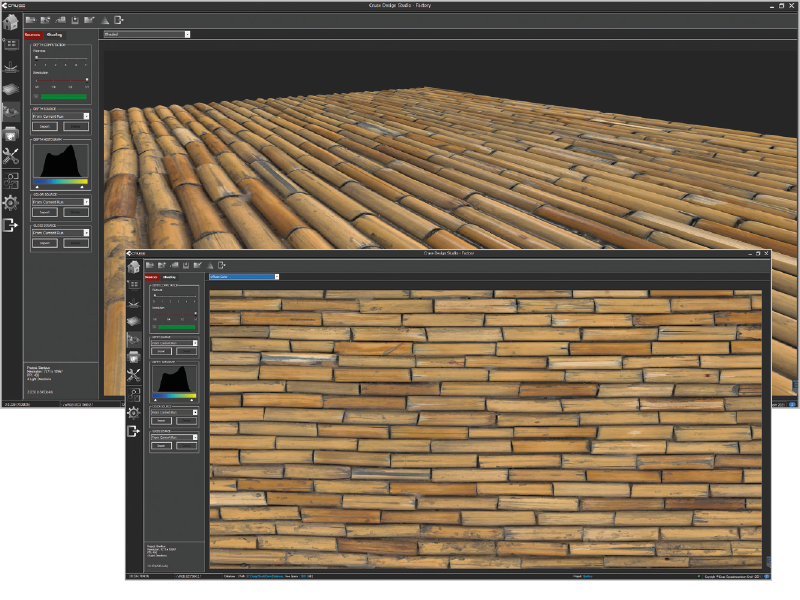

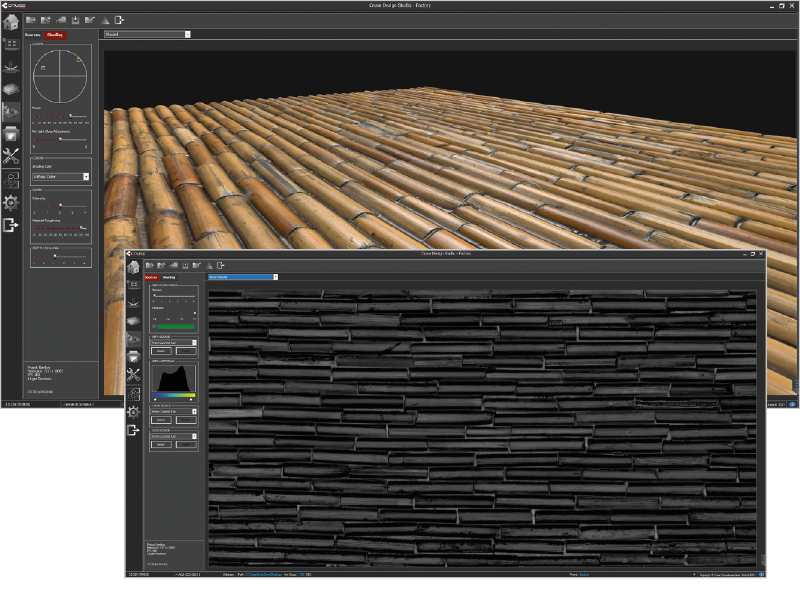

Using the photometric stereo method, the software determines the 3D structure of the scanned object, based on calibrated scans with precisely defined light and camera positions. Our Virtual Relighting technique enables the re-exposure of scans with the help of virtually defined lighting scenarios. The optimum illumination of your original can be determined very easily, and a virtually illuminated scan can be calculated, even if the original is no longer available.

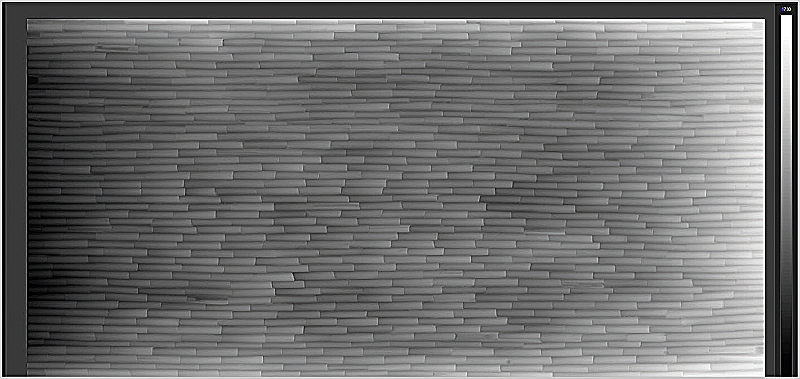

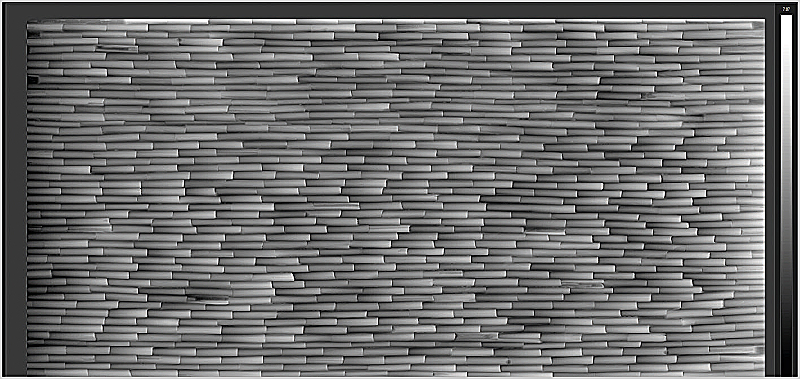

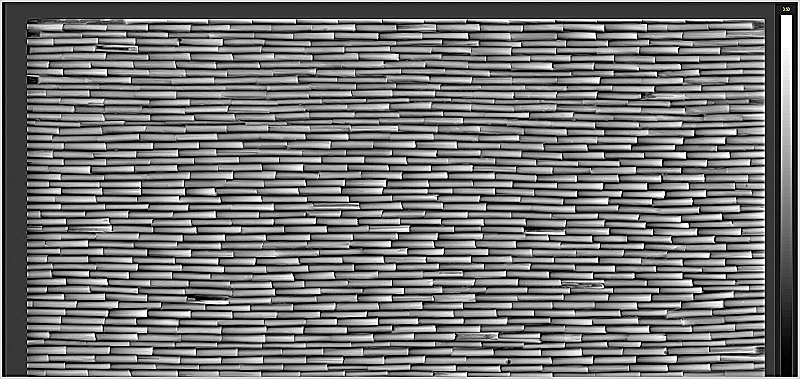

Flatness Filter with Real-Time Preview

Many times, objects are not completely flat and show a disturbing deformation, such as a sagging canvas or a warped wooden board. These deformations can be removed digitally using the integrated flatness filter.

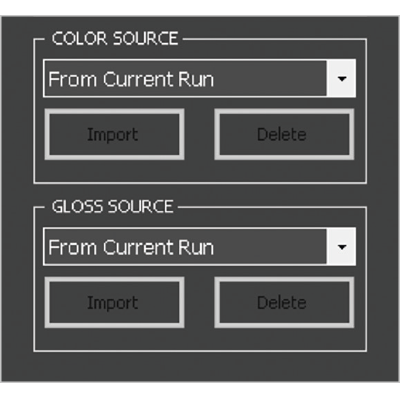

Factory also offers a variety of tools for processing all calculated information. For example, it can remove unwanted deformations found on the object with special filters, or exchange gloss, depth, or color information.

All calculations are optimized for multi-core systems and designed for very large items. Even large-format scans can be processed and displayed in real time, during the calculation. For example, parameters such as illumination, gloss, and structure of a scan can be adjusted.

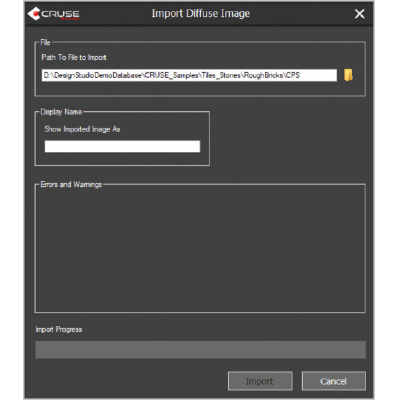

A variety of export formats ensures smooth data transfer into your workflow and enables exchange with third-party software.

Detects unevenness over the entire original.

low

medium

high

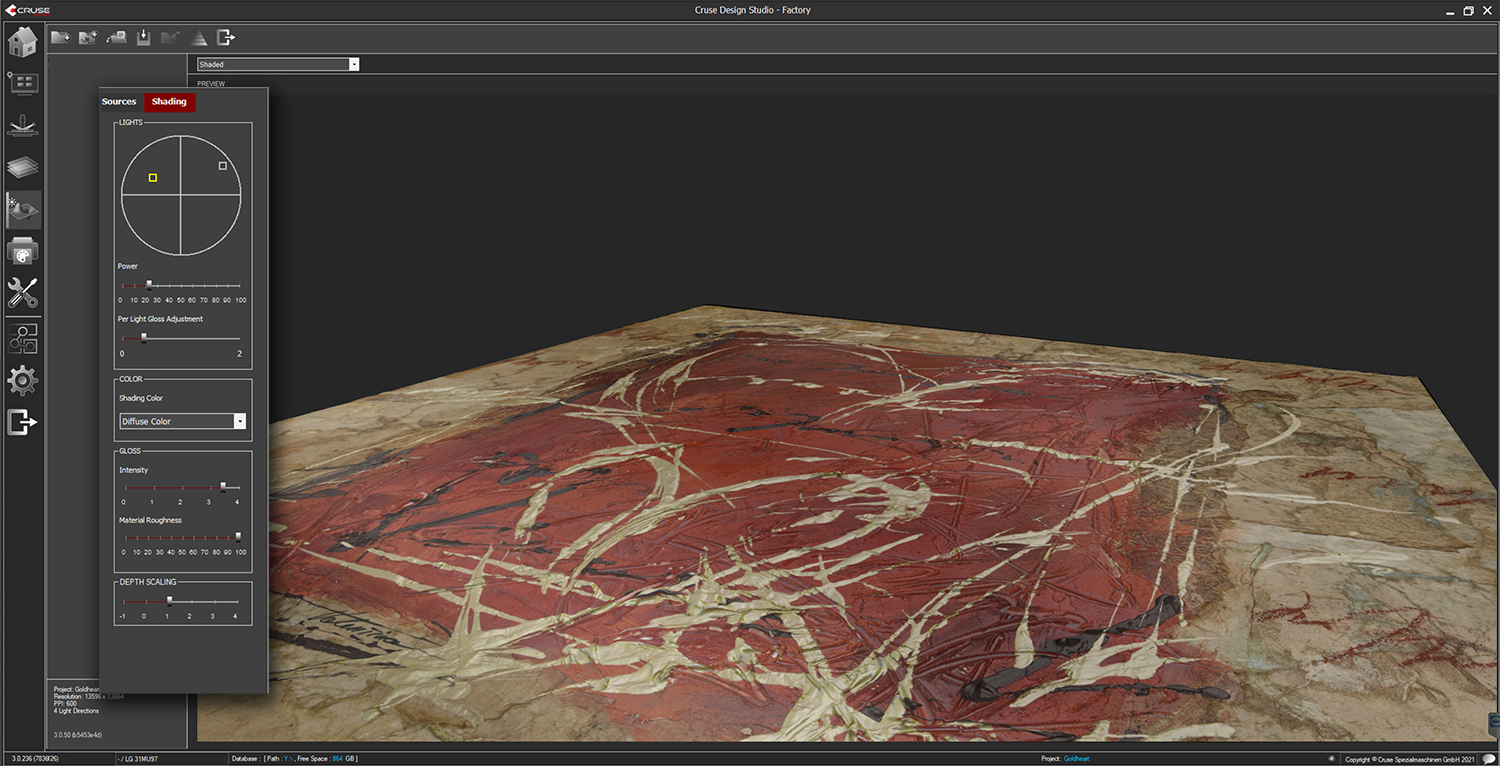

Virtual Relighting

Virtual Relighting calculates a realistic exposure from the determined color, gloss, and surface data. They influence a variety of parameters, such as:

- Lighting situation: Define lighting scenarios with any number of light sources. Light sources are positioned via an intuitive interface.

- Gloss intensity and material roughness: Specify how strong and in what manner the surface should shine.

- Surface structure: Reinforce or suppress the surface structure.

With Virtual Relighting, users have full control and can illuminate their scanned items as they like. Another advantage: new exposures are still possible even when the items are no longer available to be rescanned.

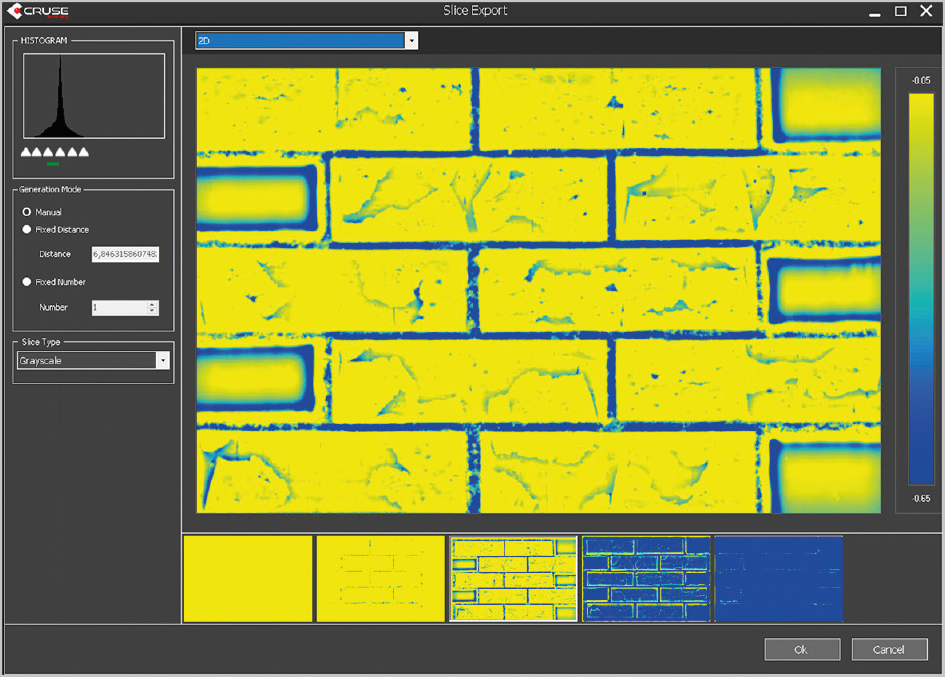

Data Export

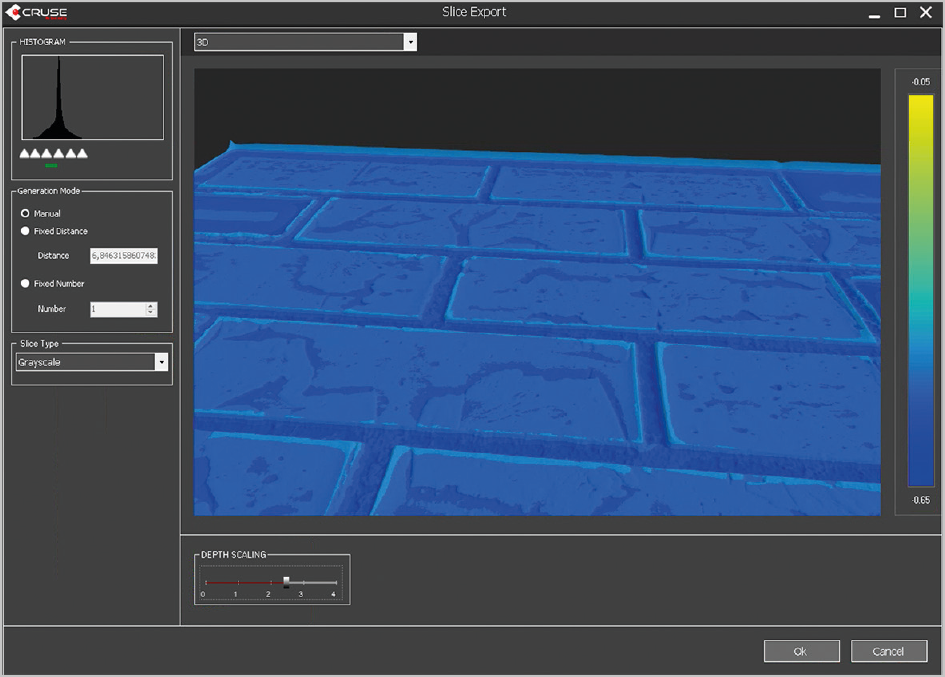

All data calculated by CRUSE Factory can be exported in a variety of formats. In the software, details can be checked before the export, both in 2D and 3D representations, and optimized if necessary. All factory exports have the exact same size and are registered with each other, so that they can be opened as layers,

for example.

Here is a selection of export options:

- Export of the surface as grayscale image

- Export of surface 3D data as Normal/Bump Map for PBR

- Export color and gloss

- Export 3D information

- Export the surface as separated masks or grayscale images (depth slicing)

- Export of virtually exposed surfaces (virtual relighting)

In addition, CRUSE Factory offers interfaces to third-party software, which are constantly extended. These third-party interfaces include:

- Export in Canon Touchstone

- Export to Roland VersaUV

- Export to swissQprint Drucker

- Export to AVA Structur Simulator